Opera 3 Service & Helpdesk Management

Opera 3 streamlines your customer contract management, helpdesk functions and communication with staff on the road.

Opera 3 Service Management is designed to maintain and renew maintenance contracts with customers. Working with Opera 3 CRM and Sales Order Processing, Service Management can provide end-to-end service and maintenance management, from Quote, Order and Delivery through to Installation, Contract, Service, Breakdown and Billing. The contract information includes value, equipment covered, billing periods and renewal date. You can also log all activities against a contract, such as site visits and Helpdesk calls, so that you have a complete picture of the contract, all in one place.

- Summary

- Features

- Service Level Agreement (SLA) call monitoring and engineer scheduling

- Skills Matching, Service Areas and Fault Analysis, with comprehensive reporting capability

- Contracts, Period Renewal Billing, Pro Rata Charging, Planned Maintenance

- Equipment (Assets) Components, Variable Service Types, Warranty and Loan Equipment

- Time, Expense and Parts Recording and Billing

- Installation Projects and Scheduling

- User-defined fields: add your own data and terminology to key forms

- Complaints, problems, change requests: full helpdesk and Knowledge Base

- Integrates with TomTom WORK

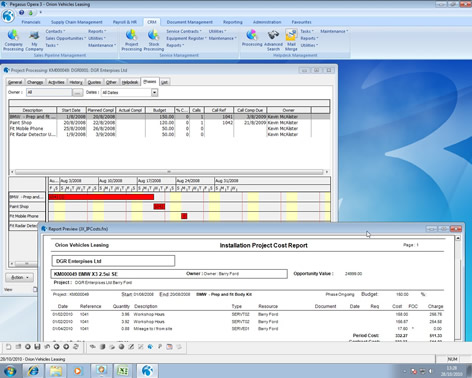

Project Processing

With Project Processing you can progress sales opportunities from CRM through to an installation project in Service Management. Project Processing is used to plan and keep track of engineers working on the delivery and installation of items sold.

The project can contain different phases such as design, preparation, groundwork, installation and so on. Each phase can be given a timescale and budget and have Helpdesk calls assigned to it. You therefore have full visibility and control over every sales opportunity or prospect and can track their progress right through to acquisition and installation.

Notification services

The Notification Services feature has been extended to the CRM application to improve Helpdesk Call communication. Notifications can be sent to users in the following scenarios; Creation of a new Helpdesk Call, the Status or Priority of an existing Helpdesk Call changing, the user receives ownership or is allocated an existing Helpdesk Call, and when a new or existing note on a Helpdesk Call has been added or amended.

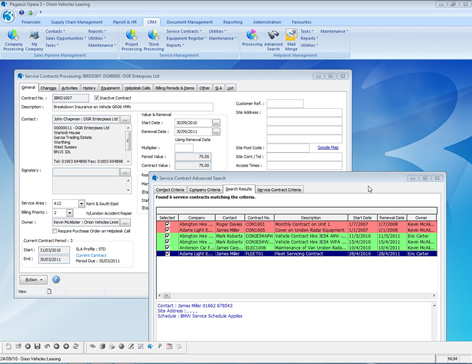

Service Contracts and Billing

With Service Contracts you can maintain a record of service contracts you have with customers and log all calls, visits, equipment used etc against each contract. Service contracts can be invoiced and documents posted to Opera 3.

Equipment Register

A register of individual products that are covered by service contracts to enhance equipment reliability and availability. It also enables the tracking of components exchanged on-site and generates relevant stock transactions.

Helpdesk Management

The Helpdesk enables you to log calls against company and individual contacts and track them through to resolution. It provides a central point for recording problems, customer complaints, installation and preventative maintenance visits required against your products, services or contracts. The Helpdesk is used when these issues need to be tracked, planned and resolved. Each call can have activities and notes or documents associated with it. There is also access to a Knowledge Base to aid swift resolution of the issue. In addition, any further calls can be linked to an original call and easily viewed.

Available call types:

- Helpdesk calls are individually numbered, date recorded and measured against configurable Service Level Agreements (SLAs). These calls initiate, collect and cost work carried out, parts used and can be raised against contacts and contracts. Call data can also contain equipment register and part coding.

- Preventative Maintenance calls are service-related calls with a planning date. These appear in the scheduling system and are also visible when organising Helpdesk calls (in case the engineer can do both at once).

- Installation calls are planned visits to install or set up equipment and can be scheduled.

- Change Requests are used for changes to the design of equipment or software which need formal control. This type of call needs planning and has documents and time spent on it. It provides a useful change history to items such as parts or Assets (Equipment) as calls progress through key stages.

Batch Generation of Planned Maintenance calls

Users can create in bulk any planned maintenance calls that may be due for Equipment Items. Users will be able to generate all calls due in one month, two months or future months; without having to create each call individually.

By running the Generate Planned Maintenance (PM) Calls routine – Calls are automatically generated based on the calculation of the Next Service Due Date and the Service Interval, and either the Last Service Due Date or the Last Service Done Date, depending on individual requirements for each Equipment Item. This allows users to easily create and keep up to date with any planned maintenance required against equipment records.

Summary Scheduler

The Summary Scheduler facility in Helpdesk Management gives users an alternative way to schedule or reschedule calls; by presenting a summary view of all resources for the chosen month. This enables calls to be scheduled in bulk, rather than from the individual calls themselves.

The Summary Scheduler provides users with an overall view of the scheduling calls over any four week period; and provides flexible filtering for accurate planning. For example, users may wish to view only engineers that work out-of-hours, or calls allocated to a specific department.

Users can easily view all calls planned for any resource and date, by simply highlighting the resource and date in question: with added drill down capabilities to individual calendar views, for more precision planning.

Calls can progress through various optional stages:

- Raised: any person can raise calls

- Allocated: the call is routed to a controller for validation, planning and action. After it has been allocated, a call can be scheduled for an engineer

- Planned: the call is loaded onto the scheduling board and an engineer is assigned to it

- Travel: the engineer is on the way

- Working: the engineer is working on site

- Completed: work is done and the call is closed

- Calls can be logged with unique references, dates, descriptions etc

- Track calls from initial logging through to resolution

- Calls can be one of different types: 'Helpdesk', 'Installation', 'Change Requests' and 'Preventative Maintenance'

- Service areas and faults codes can be assigned to calls and then analysed

- Skills Records and Asset Skill Requirements can be maintained so the right people are assigned to calls

- Engineers can be assigned to area codes

- Calls can be assigned to different teams and members of teams

- A register of solutions (Knowledge Base) can be maintained

- Reports provide analysis of calls (for example, by company, contact, product or job number)

- Performance can be monitored against a Service Level Agreement (SLA) for each customer

Key features of Service Contracts and Billing include:

- Sales Opportunities can be converted to installation contracts

- Contracts include Service Level Agreements (SLAs), contract values and multiple equipment items and renewal dates

- Multiple contract periods can be set up with numbers of free calls and free hours, hours maintained and cost per period

- Documents and e-mails relating to a contract can be attached to it

- Activities such as site visits and helpdesk calls can be logged against a contract

- Activities can be chargeable or free of charge

- Preventative Maintenance Schedules can be maintained against a contract

- Profit analysis of a contract and its Periods

- Invoices can be calculated on the full contract value or based on a pro rata value

- Invoices for chargeable items and time can be batch-posted in the Invoicing or SOP applications

- Contract renewal invoicing (including pro rata and new items mid-period)

- Time taken can be recorded against an activity, allowing time analysis

Key features of Equipment Register include:

- Maintain a complete service history for products on maintenance contracts

- Product records can be associated with Asset code serial number, original customer invoice number and/or delivery note number

- Maintain a bill of materials for individual product records detailing serial numbers of sub-assemblies, version, bug and fix information and components

- Maintain components within the bill of materials following maintenance or repair visits by recording the new serial numbers of replaced components

- Replacement components can be moved out of stock and returned components moved into stock or scrapped

- Cost analysis of component exchanges

- Warranty Tracking and Loan equipment